Gadgets

India’s Approved Semiconductor Projects to Produce Over 24 Billion Chips Annually: Official

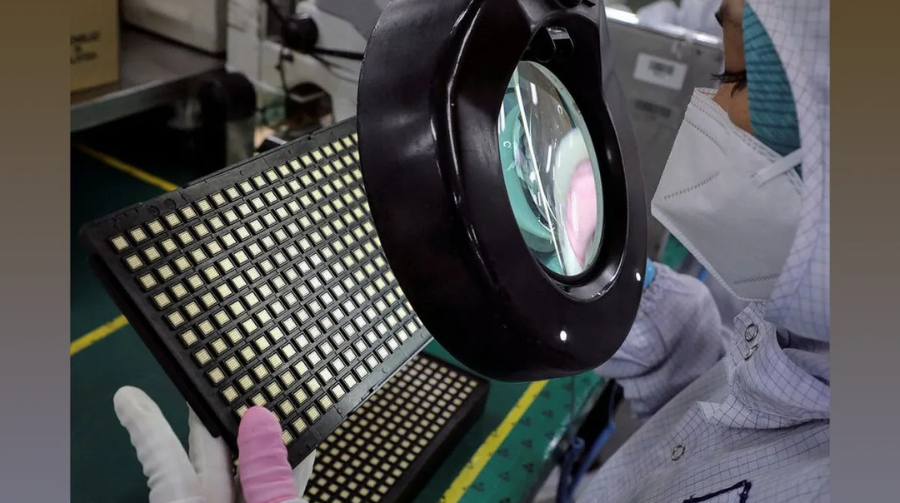

India’s semiconductor ambitions have received a major boost. According to Amitesh Sinha — Additional Secretary at the Ministry of Electronics & IT and CEO of the India Semiconductor Mission (ISM) — six government‑approved projects are projected to produce over 24 billion chips per year

- The approved portfolio includes one wafer fabrication plant (by Tata Electronics) and five packaging & test facilities.

- Tata’s fab is set up for a capacity of 50,000 wafers per month.

- The five ATMP (assembly, testing, and packaging) units will combine for the 24 billion‑chip output target annually

- More proposals are awaiting approval under ISM 1.0 and upcoming ISM 2.0, which will further expand capacity

Project Highlights

| Project | Type | Capacity | Location | Investment |

|---|---|---|---|---|

| Tata Electronics Fab | Wafers | 50 000 wafers/month | Dholera, Gujarat (plus Assam assembly plant) | ₹91 000 crore (~US$11 billion) |

| Tata Assam ATMP (Tata Semiconductor Assembly & Test) | Packaging & Test | ~48 million chips per day | Jagiroad, Assam | ₹27 000 crore (~US$3.6 billion) |

| Kaynes Technology ATMP | Packaging & Test | ~6.3 million chips per day | Sanand, Gujarat | ₹3 307 crore (~US$400 million) |

| CG Power‑Renesas/Stars Micro ATMP | Packaging & Test | ~? | Sanand, Gujarat | ₹7 600 crore (~US$900 million) |

| HCL–Foxconn OSAT (display drivers) | Packaging & Test | ~36 million chips per month (~432 million/year) | Jewar, Uttar Pradesh | ₹3 706 crore (~US$430 million) |

| Another ATMP unit (Powerchip, CG? etc.) | Packaging & Test | Remaining to total ~24 billion/year | Gujarat | — |

Combined output from these five ATMP units delivers the bulk of the 24 billion‑chip capacity per annum quoted by the official.

Strategic Significance

- These six approved projects are part of a ₹76,000 crore (≈US $10 billion) semiconductor incentive scheme launched under ISM to build India’s chip ecosystem

- ISM has been structured in phases; the first phase (ISM 1.0) is nearly fully allocated, and ISM 2.0 is on the cards to fund new proposals

- These initiatives mark India’s strategic effort to reduce dependency on chip imports, support sectors like automotive, telecom, consumer electronics, and integrate into global value chains.

Future Pipeline

- More project approvals are expected soon, including proposals from Hiranandani’s Tarq Semiconductors, Adani‑Tower Semiconductor JV, Vedanta plans in Dholera, among others

- Tata’s Dholera fab is expected to come online by 2026, producing mature-node chips (~28 nm) with eventual total capacity around 50,000 wafers/month (~20,000 skilled jobs)

- The HCL‑Foxconn unit will ramp up production by 2027, aligning with next‑gen display and automotive applications

- On the research front, IIIT Hyderabad has launched a microfabrication ‘FabLab’ to bolster India’s R&D capabilities in semiconductor technology

Why 24 Billion Chips Matter

- The 24 billion figure refers solely to annual output from packaging/testing units, not raw wafer output.

- A long‑term journey, with wafer fabs feeding downstream assembly units, the ecosystem is envisioned to scale further as newer proposals get approved.

- The capacity positioning gives India entry into the global mature-node chip segment used in power electronics, automotive ECUs, smartphones, display drivers—and lays foundation for future advanced R&D and design-based growth.

Bottom Line

As of August 1, 2025, India has approved six semiconductor projects—including one major wafer fabrication unit and five packaging/test plants—that together will produce over 24 billion chips annually. This initial wave is underpinned by ₹76,000 crore in government incentives and marks a seminal shift toward building a domestic semiconductor ecosystem. With more proposals in the pipeline and further phases of policy support (ISM 2.0), India is setting its long‑term path to chip self‑reliance and global tech relevance.